Gochang, South Korea, September 3, 2025

News Summary

Korea Electric Power Corporation has introduced S-CAP, a data-driven software tool that standardizes submarine cable protection by quantifying risk, recommending optimized protection measures and producing design reports. S-CAP accepts site-specific inputs such as anchor types, wave and current conditions, and detailed seabed properties to calculate variable burial depths and recommend alternatives like rock berms or concrete ducts. Backed by numerical modelling and full-scale tests at a large Korean testing centre, the program has received formal document verification and has been applied to a major offshore wind grid link, delivering improved transparency, lower repair risk and cost savings.

KEPCO’s S-CAP software turns submarine cable protection into a data-driven design process

The KEPCO Submarine Cable Protector (S‑CAP) is a computer-based tool that standardizes, quantifies and optimizes submarine cable protection options. It translates empirical methods into a formal, repeatable engineering workflow and outputs concrete design artifacts. A leading classification authority formally verified the method in early 2024, marking a first for a protection approach of this kind. Since then, the software has been deployed on a major Korean offshore wind connection project, illustrating the potential for cost reduction, improved documentation and clearer decision support across HVDC and AC submarine cable programs.

What the software does and how it works

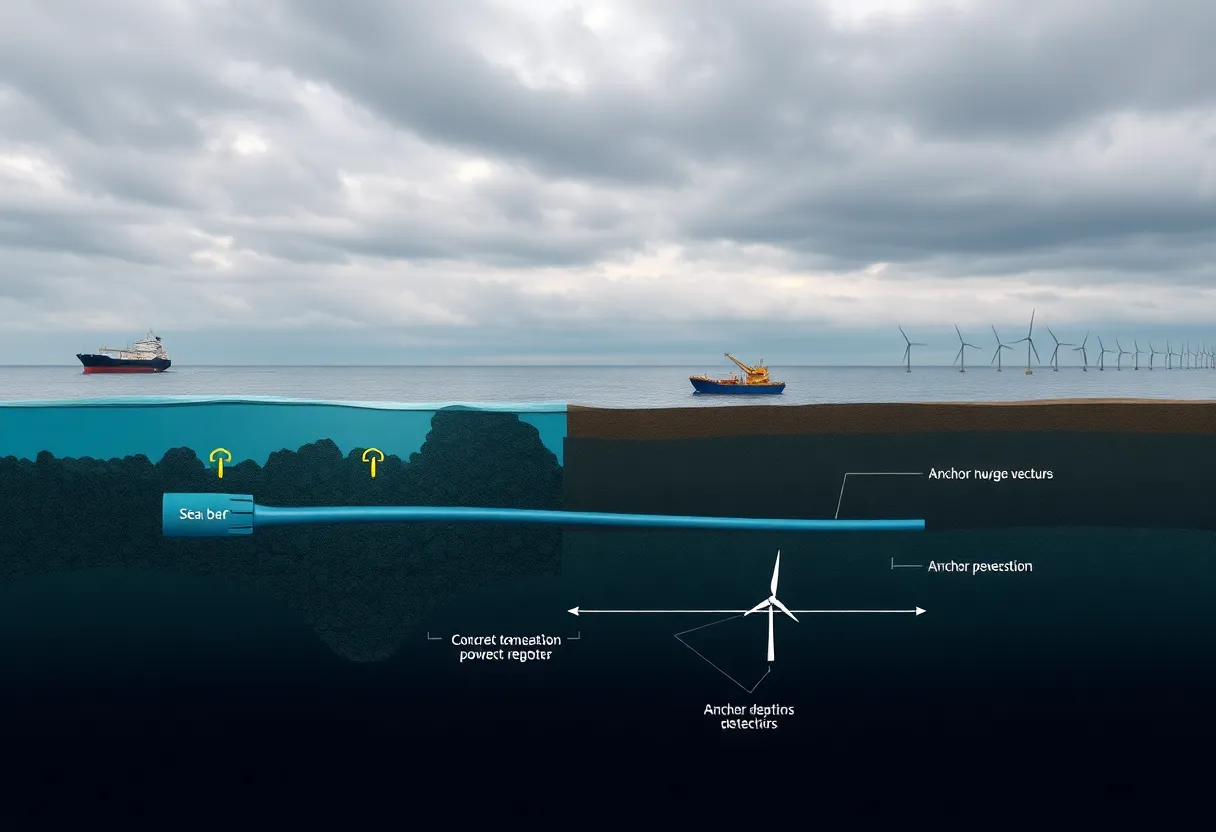

The system prompts users to enter environmental and engineering data, including anchor types and weights, wave height, current velocity, and seabed properties such as unit weight and shear strength. Using these inputs, S‑CAP automatically computes the optimal burial depth for each segment of a route and presents multiple protection options with a recommended choice. It also generates cross‑sectional drawings and a comprehensive design report.

The software is built around quantified design standards for protection methods such as burial and rock berms, with explicit specifications for berm size, material choice and installation tolerances. By applying location‑specific marine risk, S‑CAP can tailor burial depths instead of relying on a uniform, one‑size‑fits‑all approach. It also supports projects where burial alone is insufficient, offering standardized guidance for protective structures when needed.

Testing, validation and the design principle

Verification, applicability and potential impact

The software received formal document verification in February 2024 from a globally recognized classification body, a milestone for submarine cable protection methods. S‑CAP is designed to support global submarine cable projects, including offshore wind connections, HVDC transmission corridors and regional interconnections. It is applicable to both HVDC and AC submarine cables, with claims of meaningful cost efficiency gains and transparent design logic. On projects where it has been used, installation costs have shown notable reductions and environmental impacts have been minimized, while the digitized reporting format has improved trust between project owners and contractors.

Broader benefits and risk management

LS Cable & System and the Busan–Fukuoka submarine link

A consortium is planning a state‑of‑the‑art undersea telecom link spanning approximately 260 km between Busan, South Korea and Fukuoka, Japan, with completion anticipated by 2027. LS Cable & System, together with its subsidiary LS Marine Solutions, has secured the project on a turnkey basis to deliver the cable system end‑to‑end. This project marks a major international submarine cable contract for LS Cable & System, reflecting its broader push into offshore cable work and renewable energy initiatives. The JAKO cable is designed to bolster connectivity between the two nations and to support mounting demands of AI workloads and cloud services in Northeast Asia, with industry observers noting that the network is positioned to handle rising data traffic driven by major cloud platform expansion. LS Cable & System has a long history in cable manufacturing and installation services for HVDC systems, renewable energy cables and submarine telecom cables, and aims to oversee the full EPC process to deliver a future‑proof link. The JAKO cable is viewed as a strategic response to growing regional infrastructure needs amid increasing geopolitical and economic ties across Asia.

E2A subsea cable linking East Asia and the United States

Construction is underway on a new subsea cable linking East Asia and the United States. The E2A cable is planned to span roughly 12,500 km with landing points at Toucheng, Taiwan; Busan, South Korea; Maruyama, Japan; and Morro Bay, California. The line is being built by Alcatel Submarine Networks and will carry a capacity greater than 192 Tbps across 12 fiber pairs. A 18 kV power technology system is included, and the project is slated to go live in the second half of 2028. The E2A consortium comprises SoftBank, SK Broadband, Chunghwa Telecom and Verizon. SoftBank will provide its landing station in Japan for the project. Industry commentary emphasizes that submarine cables are increasingly viewed as essential arteries of information in the AI era, and the consortium intends to advance global, stable platforms by expanding infrastructure for AI workloads. In parallel, large multinational technology firms have announced plans to invest in additional routes, highlighting ongoing growth in transpacific undersea connectivity. The E2A project sits within a broader ecosystem of cables that connect the U.S. West Coast to Asia through multiple existing routes.

Practical implications for design, cost and risk

Across these initiatives, the emphasis remains on transforming protection decisions from experience‑based judgment to a quantified, auditable design process. The goal is to safeguard critical links for offshore wind, telecommunications and cross‑regional energy flows while controlling costs and minimizing environmental impact. The combination of standardized engineering standards, validated methods and transparent reporting aims to support dependable transmission and resilient connectivity in a changing global energy and information landscape.

Key takeaways

- Data‑driven design replaces purely empirical methods in submarine cable protection.

- Burial depth optimization accounts for local anchor risks and seabed properties.

- Standards for protective structures (rock berms, etc.) are codified and integrated into the design workflow.

- Verification by an independent classification body adds credibility to the method and its outputs.

- Early cost reductions and environmental improvements are reported on pilot projects, with potential global applicability.

FAQ

Frequently asked questions

What is KEPCO S‑CAP?

A software tool that suggests quantitatively optimized submarine cable protection options and generates a complete design package, based on standardized protective criteria.

What verification did S‑CAP receive and when?

The method received formal document verification from a globally recognized classification body in February 2024, identifying the approach as scientifically rigorous and applicable to real projects.

What kinds of projects is S‑CAP designed to support?

It is designed for submarine cable projects across offshore wind connections, HVDC transmission corridors and interregional energy links, covering both HVDC and AC systems.

What practical outcomes have been reported from using S‑CAP?

Reported outcomes include reduced installation costs, streamlined documentation, and improved transparency in design decisions, along with minimized environmental impact on projects where the software was applied.

What is the E2A subsea cable?

The E2A subsea cable is a long‑haul link planned to connect East Asia with the United States, featuring a large capacity across multiple fiber pairs and powered elements, with a live timeline targeting the second half of 2028.

Key features table

| Feature | Description |

|---|---|

| Data‑driven protection design | Converts empirical practice into standardized, quantitative design inputs and outputs. |

| Burial depth optimization | Calculates segment‑level burial depths based on anchor risk, seabed properties and safety margins. |

| Protective structures standards | Includes specifications for rock berms and other protective elements with installation tolerances. |

| Cross‑sectional drawings and reports | Generates design drawings and a comprehensive report for documentation and traceability. |

| Validation and applicability | Validated by a recognized body and applicable to HVDC and AC submarine cables for offshore wind, interconnections and regional links. |

| Cost and environmental impact | Reported reductions in installation costs and environmental footprint on pilot deployments. |

Deeper Dive: News & Info About This Topic

Additional Resources

- Korea JoongAng Daily: LS Cable wins $115M submarine cable order from Taiwan

- Wikipedia: LS Cable & System

- Capacity Media: LS Cable joins Korea–Japan submarine cable project

- Google Search: Korea Japan submarine cable Busan Fukuoka

- Financial Times: Subsea cable / industry coverage

- Google Scholar: submarine cable protection anchor penetration

- DataCenter Dynamics: Construction begins on E2A subsea cable connecting US to Asia

- Encyclopedia Britannica: E2A subsea cable

- Inspenet: Taihan secures subsea cable contract for Korea offshore wind project

- Google News: Taihan subsea cable Korea offshore wind